- Analytics & Modeling - Edge Analytics

- Infrastructure as a Service (IaaS)

- Process Manufacturing

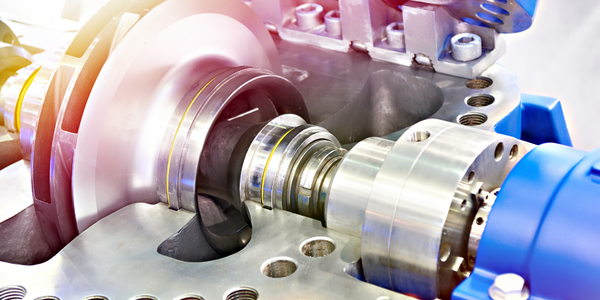

- Machine Condition Monitoring

Cavitation is a condition can occur in centrifugal pumps when there is a sudden reduction in fluid pressure. Pressure reduction lowers the boiling point of liquids, resulting in the production of vapor bubbles if boiling occurs. This is more likely to happen at the inlet of the pump where pressure is typically lowest. As the vapor bubbles move towards the outlet of the pump where pressure is higher, they rapidly collapse (return to a liquid state) resulting in shock waves that can damage pump components.

An intelligent edge solution can ingest pump sensor data in real-time and apply mathematical equations on the incoming data to identify any significant changes in pressure and alert operations personnel before damage occurs. It can also send a signal to the main system to automatically move the flow of the fluid to a different pump to prevent damage and reduce maintenance and downtime costs associated with pump cavitation.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.