- Analytics & Modeling - Virtual & Augmented Reality Software

- Wearables - Augmented Reality Glasses, Headsets & Controllers

- Telecommunications

- Maintenance

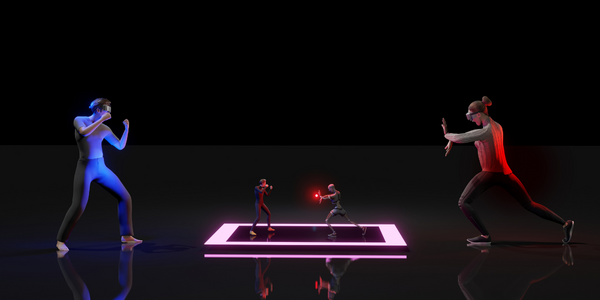

- Remote Collaboration

The project presented a series of technical and organizational challenges to the partners. First, the team members collaborating on the project were located in different regions of the world (US, Europe and China) and all development and testing had to be performed remotely.

Huawei required that the application rely entirely on 3D Object Tracking. Finally, the solution had to work outdoors, in highly variable climatic and lighting conditions in which the SUN2000 inverters are usually installed.

The AR experience was created rapidly based on a detailed storyboard and using the HyperIndustry platform, an Experience Management System for Industry 4.0. The platform compiles all the necessary content and interactive modules into native mobile applications for use on Android and iOS smartphones and tablets.

First the technician can choose either English or Mandarin instructions. The AR experience starts when the technician points the camera of the mobile device on which the application is running at the inverter. The target is automatically recognized, and a list of procedures available for the model appears on the screen. The procedures may be assigned by the maintenance manager to one or more technicians, or they can be initiated entirely by the engineer in the field.

this allows field technicians to independently perform technical procedures by executing all required steps.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.