- Analytics & Modeling - Machine Learning

- Analytics & Modeling - Predictive Analytics

- Infrastructure as a Service (IaaS)

- Networks & Connectivity - Gateways

- Oil & Gas

- Maintenance

- Machine Condition Monitoring

- Predictive Maintenance

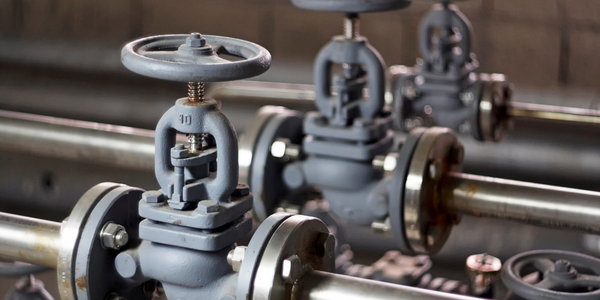

Ham-Let is a leading manufacturer of valves, fittings and instrumentation. One of the key challenges in this industry is identifying malfunctions and shutting off the appropriate valves before any damage can be done. However, it is often a demanding task to identify the cause of the malfunction and isolate the valves quickly.

Valves of the past had a simple function: allow flow or shut off flow. A smart valve that is capable of continuously monitoring the current diaphragm condition using acquired acoustic data, thus enables autonomous predictive maintenance.

The H800L IoT Valve is an industrial solution which includes valve and gateway device management. Each valve's parameters and historical data can be retrieved including the number of times the valve has been opened and closed in addition to manufacturing and test data.

Moreover, through the use of machine learning and audio machine learning models we can analyse the valve's open and close parameters respectively and therefore identify unusual or outlying conditions.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.